420 Mpa

Pipes centrifugally cast with push-in flexible joints and weld-on flange joints

10% ≤ DN 1000

7% ≥ DN 1100

Pipes not centrifugally cast with cast-on flange joints and Fittings

5%

Pipes centrifugally cast with push-in flexible joints and weld-on flange joints

230 HBW

Pipes not centrifugally cast with cast-on flange joints and Fittings

250 HBW

Pipes centrifugally cast with push-in flexible joints and weld-on flange joints

minimum 3°30' for DN 80 to DN 300

minimum 2°30' for DN 350 to DN 600

minimum 1°30' for DN 700 to DN 1000

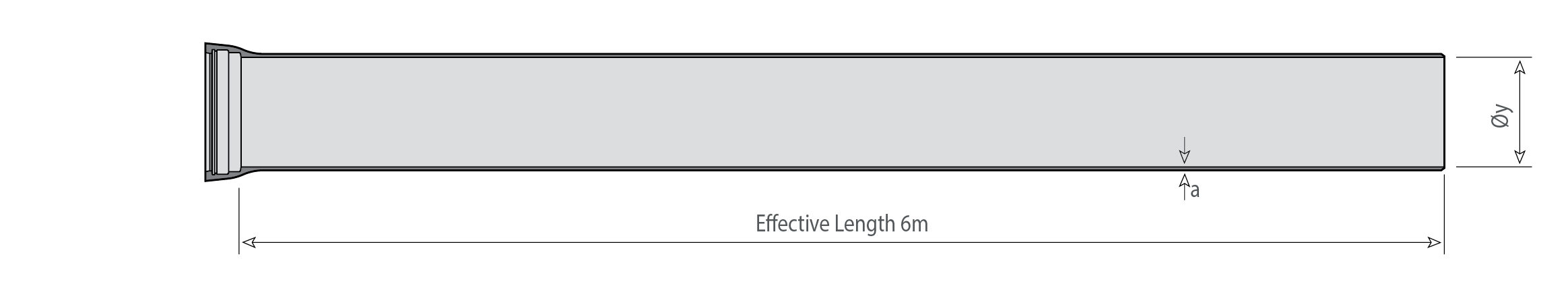

Flexible pressure pipelines carrying water, sewage and other liquids.

For thickness of cement lining see technical details

Nominal Size |

Mean External Diameter |

Cement Lined Mean Internal Diameter |

Nominal Wall Thickness |

Allowable Operating Pressure* |

Allowable Maximum Operating Pressure** |

Allowable Site Test Pressure† |

DN |

mm |

mm |

mm |

MPa |

MPa |

MPa |

80 |

98 |

78.0 |

6.0 |

6.4 |

7.7 |

9.6 |

100 |

118 |

98.0 |

6.0 |

6.4 |

7.7 |

9.6 |

150 |

170 |

150.0 |

6.0 |

6.4 |

7.7 |

9.6 |

200 |

222 |

201.4 |

6.3 |

6.2 |

7.4 |

7.9 |

250 |

274 |

252.4 |

6.8 |

5.4 |

6.5 |

7.0 |

300 |

326 |

303.6 |

7.2 |

4.9 |

5.9 |

6.4 |

350 |

378 |

352.6 |

7.7 |

4.5 |

5.4 |

5.9 |

400 |

429 |

402.8 |

8.1 |

4.2 |

5.1 |

5.6 |

450 |

480 |

452.8 |

8.6 |

4.0 |

4.8 |

5.3 |

500 |

532 |

504.0 |

9.0 |

3.8 |

4.6 |

5.1 |

600 |

635 |

605.2 |

9.9 |

3.6 |

4.3 |

4.8 |

700 |

738 |

704.4 |

10.8 |

3.4 |

4.1 |

4.6 |

800 |

842 |

806.6 |

11.7 |

3.2 |

3.8 |

4.3 |

900 |

945 |

907.8 |

12.6 |

3.1 |

3.7 |

4.2 |

1000 |

1048 |

1009.0 |

13.5 |

3.0 |

3.6 |

4.1 |

> 1000mm Refer to your SuperTYT representative |

||||||

* Allowable Operating Pressure – Internal pressure, excluding surge, which the pipeline can safely withstand in permanent service.

** Allowable Maximum Operating Pressure – Maximum internal pressure including surge, which the pipeline can safely withstand in service.

† Allowable Site Test Pressure – Maximum hydrostatic pressure applied on site to a newly installed pipeline, for a relatively short duration.

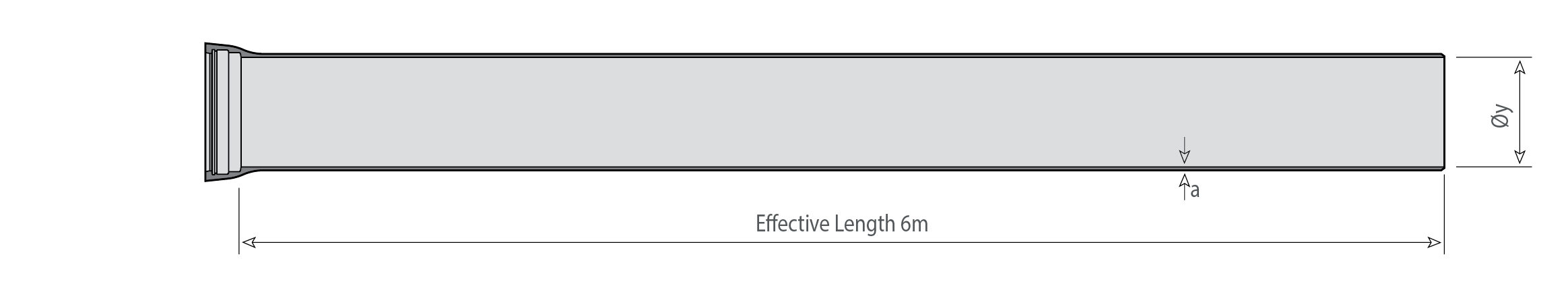

Flexible pressure pipelines carrying water, sewage and other liquids.

For thickness of cement lining see ???.

Nominal Size |

Mean External Diameter |

Cement Lined Mean Internal Diameter |

Nominal Wall Thickness |

Allowable Operating Pressure* |

Allowable Maximum Operating Pressure** |

Allowable Site Test Pressure† |

DN |

mm |

mm |

mm |

MPa |

MPa |

MPa |

80 |

98 |

76.0 |

7.0 |

6.4 |

7.7 |

9.6 |

100 |

118 |

95.6 |

7.2 |

6.4 |

7.7 |

9.6 |

150 |

170 |

146.4 |

7.8 |

6.4 |

7.7 |

9.6 |

200 |

222 |

197.2 |

8.4 |

6.4 |

7.7 |

9.6 |

250 |

274 |

248.0 |

9.0 |

6.4 |

7.7 |

9.6 |

300 |

326 |

298.8 |

9.6 |

6.4 |

7.7 |

9.6 |

350 |

378 |

347.6 |

10.2 |

6.4 |

7.7 |

9.6 |

400 |

429 |

397.4 |

10.8 |

6.1 |

7.3 |

7.8 |

450 |

480 |

447.2 |

11.4 |

5.7 |

6.8 |

7.3 |

500 |

532 |

498.0 |

12.0 |

5.5 |

6.6 |

7.1 |

600 |

635 |

598.6 |

13.2 |

5.1 |

6.1 |

6.6 |

700 |

738 |

697.2 |

14.4 |

4.8 |

5.8 |

6.3 |

800 |

842 |

798.8 |

15.6 |

4.6 |

5.5 |

6.0 |

900 |

945 |

899.4 |

16.8 |

4.4 |

5.3 |

5.8 |

1000 |

1048 |

1000.0 |

18.0 |

4.3 |

5.2 |

5.7 |

>1000 Refer to your SuperTYT representative |

||||||

* Allowable Operating Pressure – Internal pressure, excluding surge, which the pipeline can safely withstand in permanent service.

** Allowable Maximum Operating Pressure – Maximum internal pressure including surge, which the pipeline can safely withstand in service.

† Allowable Site Test Pressure – Maximum hydrostatic pressure applied on site to a newly installed pipeline, for a relatively short duration.

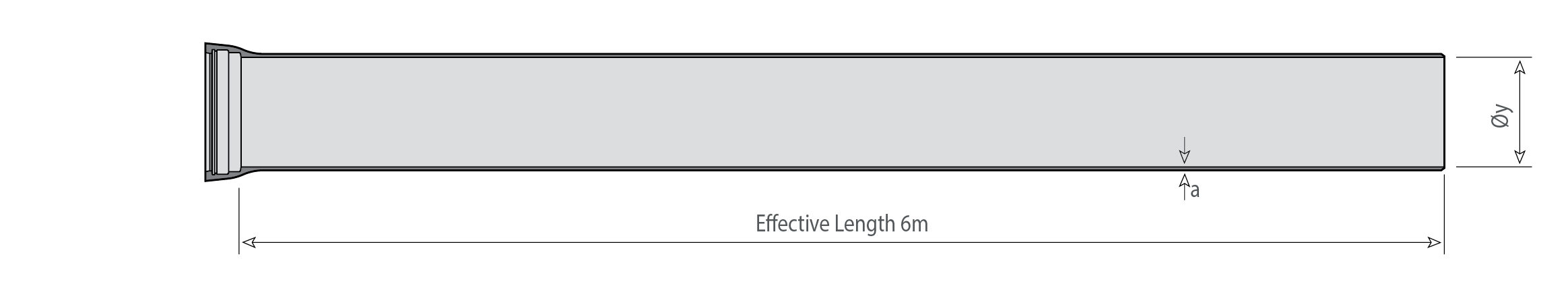

Flexible pressure pipelines carrying water, sewage and other liquids.

For thickness of cement lining see our technical section

Minimum wall thickness mm |

||||||

DN |

Class 25 |

Class 30 |

Class 40 |

Class 50 |

Class 64 |

Class 100 |

80 |

3.0 |

3.5 |

4.0 |

4.7 |

||

100 |

3.0 |

3.5 |

4.0 |

4.7 |

||

150 |

3.0 |

3.5 |

4.0 |

5.9 |

||

200 |

3.1 |

3.9 |

5.0 |

7.7 |

||

250 |

3.9 |

4.8 |

6.1 |

9.5 |

||

300 |

4.6 |

5.7 |

7.3 |

11.2 |

||

350 |

4.7 |

5.3 |

6.6 |

8.5 |

13.0 |

|

400 |

4.8 |

6.0 |

7.5 |

9.6 |

14.8 |

|

450 |

5.1 |

6.8 |

8.4 |

10.7 |

16.6 |

|

500 |

5.6 |

7.5 |

9.3 |

11.9 |

18.3 |

|

600 |

6.7 |

8.9 |

11.1 |

14.2 |

21.9 |

|

700 |

6.8 |

7.8 |

10.4 |

13.0 |

16.5 |

|

800 |

7.5 |

8.9 |

11.9 |

14.8 |

18.8 |

|

900 |

8.4 |

10.0 |

13.3 |

16.6 |

||

1000 |

9.3 |

11.1 |

14.8 |

18.4 |

||

>1000 Refer to your SuperTYT representative |

||||||

Flanged pipes are now in world-wide general use. Flanged jointed pipe should not be used to support itself as a structure in pumping station pipework or similar. Sufficient support brackets should be used to prevent flanges taking moments due to self-weight.

Pipe flanges manufactured from ductile iron may be PN16 or PN25.

An epoxy resin is used as the flange thread sealant. Unaffected by water, sewage and aqueous industrial waste, it cures to a hard clear corrosion resistant and corrosion protective solid. The resin is resistant to water absorption and will not impart colour, odour, taste or toxic constituents to potable water.

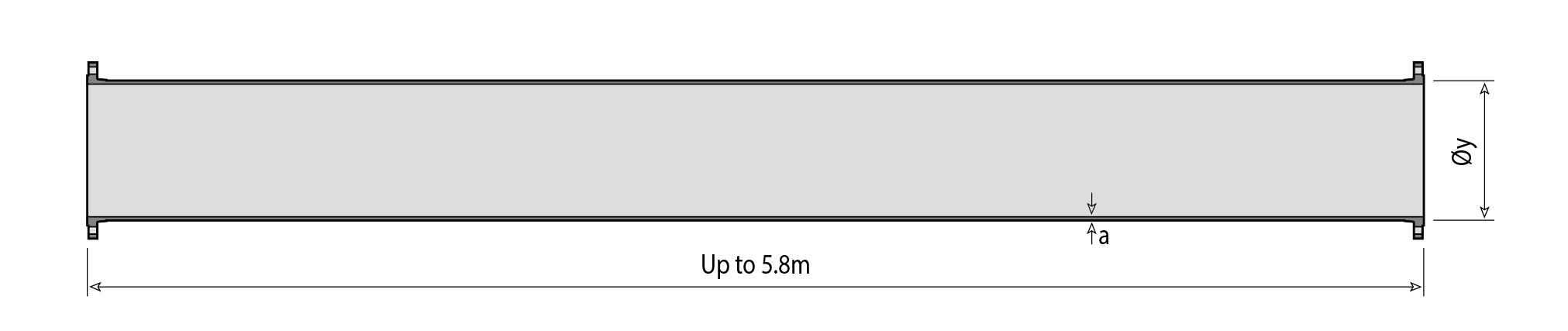

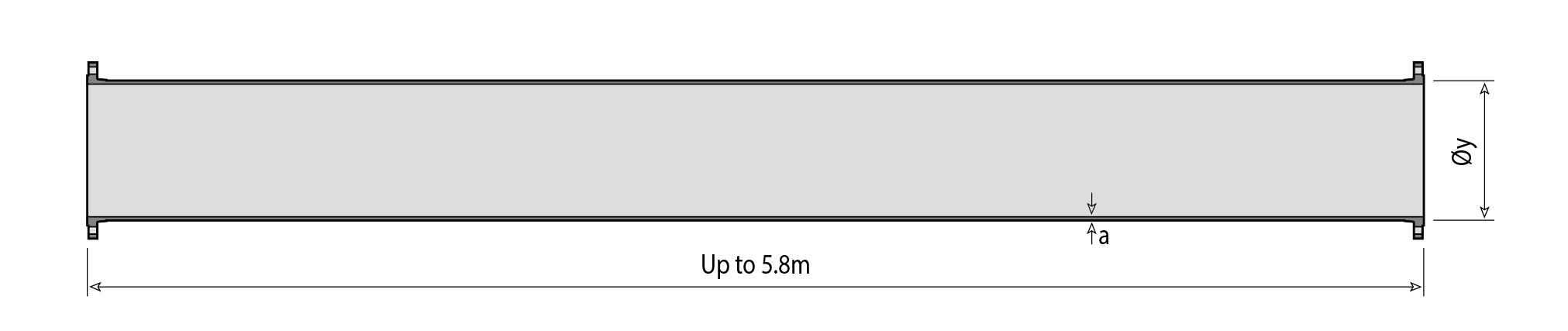

Ductile iron pipe barrels are normally supplied as Class K12. Pipe barrels of other Classes are available. The approximate Maximum length of pipe with factory Weld-on flanges and Screw-on flanges are 5.7m and 5.8m respectively.

Minimum and Maximum pipe length of Integrally Cast-On flanges |

||

Nominal Size |

Min |

Max |

DN |

mm |

mm |

80 |

200 |

1000 |

100 |

200 |

1000 |

150 |

200 |

1200 |

200 |

200 |

1200 |

250 |

200 |

1200 |

300 |

200 |

1500 |

350 |

200 |

1500 |

400 |

200 |

1800 |

450 |

200 |

1800 |

500 |

250 |

2000 |

600 |

250 |

2000 |

700 |

300 |

2000 |

800 |

300 |

2000 |

900 |

200 |

2000 |

1000 |

200 |

2000 |

Refer to your SuperTYT representative for other flanged pipes lengths. All lengths are approximates |

||

Minimum Pipe length of double flanged pipe with Weld-on and Screw-on flanges |

||

Nominal Size |

Weld-on Flange |

screw-on flange |

DN |

mm |

mm |

80 |

300 |

150 |

100 |

300 |

150 |

150 |

400 |

150 |

200 |

400 |

200 |

250 |

500 |

200 |

300 |

500 |

200 |

350 |

600 |

200 |

400 |

600 |

200 |

450 |

600 |

200 |

500 |

600 |

250 |

600 |

850 |

250 |

700 |

850 |

300 |

800 |

850 |

300 |

900 |

900 |

300 |

1000 |

1000 |

300 |

Refer to your SuperTYT representative for other flanged pipe lengths. All lengths are approximates |

||

Nominal Size |

Mean External Diameter Øy |

Cement Lined Mean ID |

NOMINAL WALL THICKNESS FOR CLASS K12 PIPE BARREL a |

Allowable Operating Pressure* |

Allowable Maximum Operating Pressure** |

Allowable Site Test |

|||

PN16 |

PN25 |

PN16 |

PN25 |

PN16 |

PN25 |

||||

DN |

mm |

mm |

mm |

MPa |

MPa |

MPa |

MPa |

MPa |

MPa |

80 |

98 |

76.0 |

7.0 |

1.6 |

2.5 |

2.0 |

3.0 |

2.5 |

3.5 |

100 |

118 |

95.6 |

7.2 |

1.6 |

2.5 |

2.0 |

3.0 |

2.5 |

3.5 |

150 |

170 |

146.4 |

7.8 |

1.6 |

2.5 |

2.0 |

3.0 |

2.5 |

3.5 |

200 |

222 |

197.2 |

8.4 |

1.6 |

2.5 |

2.0 |

3.0 |

2.5 |

3.5 |

250 |

274 |

248.0 |

9.0 |

1.6 |

2.5 |

2.0 |

3.0 |

2.5 |

3.5 |

300 |

326 |

298.8 |

9.6 |

1.6 |

2.5 |

2.0 |

3.0 |

2.5 |

3.5 |

350 |

378 |

347.6 |

10.2 |

1.6 |

2.5 |

2.0 |

3.0 |

2.5 |

3.5 |

400 |

429 |

397.4 |

10.8 |

1.6 |

2.5 |

2.0 |

3.0 |

2.5 |

3.5 |

450 |

480 |

447.2 |

11.4 |

1.6 |

2.5 |

2.0 |

3.0 |

2.5 |

3.5 |

500 |

532 |

498.0 |

12.0 |

1.6 |

2.5 |

2.0 |

3.0 |

2.5 |

3.5 |

600 |

635 |

598.6 |

13.2 |

1.6 |

2.5 |

2.0 |

3.0 |

2.5 |

3.5 |

700 |

738 |

697.2 |

14.4 |

1.6 |

2.5 |

2.0 |

3.0 |

2.5 |

3.5 |

800 |

842 |

798.8 |

15.6 |

1.6 |

2.5 |

2.0 |

3.0 |

2.5 |

3.5 |

900 |

945 |

889.4 |

16.8 |

1.6 |

2.5 |

2.0 |

3.0 |

2.5 |

3.5 |

1000 |

1048 |

1000.0 |

18.0 |

1.6 |

2.5 |

2.0 |

3.0 |

2.5 |

3.5 |

* Allowable Operating Pressure – Internal pressure, excluding surge, which the pipeline can safely withstand in permanent service.

** Allowable Maximum Operating Pressure – Maximum internal pressure including surge, which the pipeline can safely withstand in service.

† Allowable Site Test Pressure – Maximum hydrostatic pressure applied on site to a newly installed pipeline, for a relatively short duration.

Flanged joints are completely rigid and should not be used for applications where movement of the pipeline is expected, unless special provision is made to accommodate it by, for example, the inclusion of expansion joints.

A pipeline totally constructed from flanged pipework is

considered to be self-anchoring and therefore external anchorages are not required at changes of direction and at blank ends.

The joint is used mainly for ‘above ground’ applications, e.g. pumping stations, water and sewage treatment plants and for industrial pipework. It is also used to facilitate the installation and removal of valves in spigot and socket pipelines and for valve by-pass arrangements.

Particular attention should be paid to pipelines where flanged joint pipe and fittings are to be combined with Push-in Flexible pipe and fittings. In this case, thrust blocks should not be omitted from flanged bends, tees and blank ends before ensuring that there is a sufficient anchoring length of flanged pipe in the ground to prevent the flanged joint and push-in joint sections separating at the change-over points due to the effects of internal pressure.

Flanges are attached to pipes by screwing the pipe and flange with mating threads. These are filled with a recommended epoxy resin before tightening to a predetermined torque. Machining of the flanges is carried out after tightening to ensure ends are parallel and flat. Screwed and integrally cast flanges are available on request. Flanges on fittings are integrally cast in sand moulds with the body of the fitting.

PN16 Flanges |

||||||||

Nominal Size |

Flange Dimensions |

Bolting Details |

||||||

Diameter |

Thickness |

Diameter of Raised Face |

Height of Raised Face |

Pitch Circle Diameter |

Number of Holes |

Diameter of Holes |

Fastener Size and Thread |

|

DN |

D |

T |

F |

t |

P |

N |

V |

|

80 |

200 |

19.0 |

132 |

3 |

160 |

8 |

19 |

M16 |

100 |

220 |

19.0 |

156 |

3 |

180 |

8 |

19 |

M16 |

150 |

285 |

19.0 |

211 |

3 |

240 |

8 |

23 |

M20 |

200 |

340 |

20.0 |

266 |

3 |

295 |

12 |

23 |

M20 |

250 |

400 |

22.0 |

319 |

3 |

355 |

12 |

28 |

M24 |

300 |

455 |

24.5 |

370 |

4 |

410 |

12 |

28 |

M24 |

350 |

520 |

26.5 |

429 |

4 |

470 |

16 |

28 |

M24 |

400 |

580 |

28.0 |

480 |

4 |

525 |

16 |

31 |

M27 |

450 |

640 |

30.0 |

548 |

4 |

585 |

20 |

31 |

M27 |

500 |

715 |

31.5 |

609 |

4 |

650 |

20 |

34 |

M30 |

600 |

840 |

36.0 |

720 |

5 |

770 |

20 |

37 |

M33 |

700 |

910 |

39.5 |

794 |

5 |

840 |

24 |

37 |

M33 |

800 |

1025 |

43.0 |

901 |

5 |

950 |

24 |

40 |

M36 |

900 |

1125 |

46.5 |

1001 |

5 |

1050 |

28 |

40 |

M36 |

1000 |

1255 |

50.0 |

1112 |

5 |

1170 |

28 |

43 |

M39 |

PN25 Flanges |

||||||||

Nominal Size |

Flange Dimensions |

Bolting Details |

||||||

Diameter |

Thickness |

Diameter of Raised Face |

Height of Raised Face |

Pitch Circle Diameter |

Number of Holes |

Diameter of Holes |

Fastener Size and Thread |

|

DN |

D |

T |

F |

t |

P |

N |

V |

|

80 |

200 |

19.0 |

132 |

3 |

160 |

8 |

19 |

M16 |

100 |

235 |

19.0 |

156 |

3 |

190 |

8 |

23 |

M20 |

150 |

300 |

20.0 |

211 |

3 |

250 |

8 |

28 |

M24 |

200 |

360 |

22.0 |

274 |

3 |

310 |

12 |

28 |

M24 |

250 |

425 |

24.5 |

330 |

3 |

370 |

12 |

31 |

M27 |

300 |

485 |

27.5 |

389 |

4 |

430 |

16 |

31 |

M27 |

350 |

555 |

30.0 |

448 |

4 |

490 |

16 |

34 |

M30 |

400 |

620 |

32.0 |

503 |

4 |

550 |

16 |

37 |

M33 |

450 |

670 |

34.5 |

548 |

4 |

600 |

20 |

37 |

M33 |

500 |

730 |

36.5 |

609 |

4 |

660 |

20 |

37 |

M33 |

600 |

845 |

42.0 |

720 |

5 |

770 |

20 |

40 |

M36 |

700 |

960 |

46.5 |

820 |

5 |

875 |

24 |

43 |

M39 |

800 |

1085 |

51.0 |

928 |

5 |

990 |

24 |

49 |

M45 |

900 |

1185 |

55.5 |

1028.5 |

5 |

1090 |

28 |

49 |

M45 |

1000 |

1320 |

60.0 |

1140 |

5 |

1210 |

28 |

56 |

M52 |

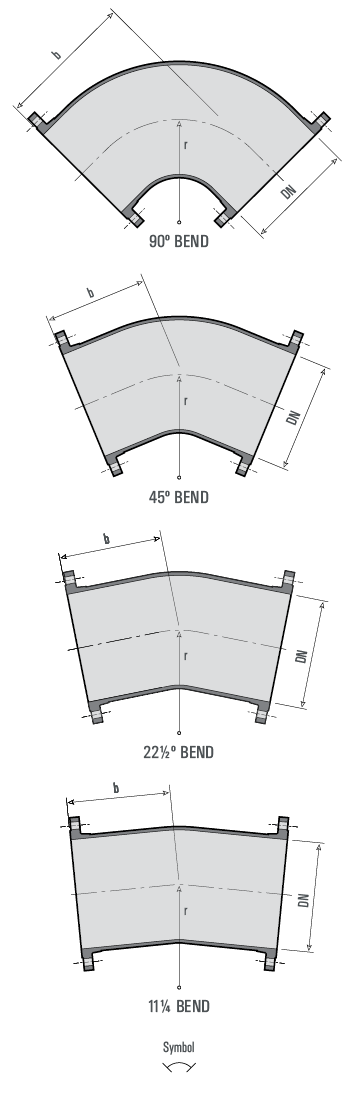

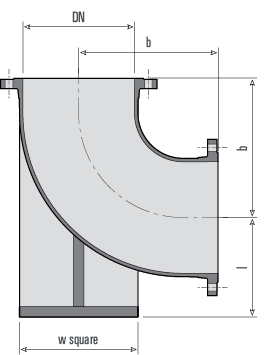

Nominal Size |

Dimension |

|||

b |

||||

DN |

11¼˚ Bends |

22½˚ Bends |

45˚ Bends |

90˚ Bends |

80 |

30 |

40 |

55 |

100 |

100 |

30 |

40 |

65 |

120 |

150 |

35 |

55 |

85 |

170 |

200 |

40 |

65 |

110 |

220 |

250 |

50 |

75 |

130 |

270 |

300 |

55 |

85 |

150 |

320 |

M350 |

60 |

95 |

175 |

370 |

M400 |

65 |

110 |

195 |

420 |

M450 |

70 |

120 |

220 |

470 |

M500 |

75 |

130 |

240 |

520 |

M600 |

85 |

150 |

285 |

620 |

M700 |

95 |

175 |

330 |

720 |

M800 |

110 |

195 |

370 |

820 |

M900 |

120 |

220 |

415 |

920 |

M1000 |

130 |

240 |

460 |

1020 |

For sizes above DN1000 please refer to SuperTYT Australia. |

||||

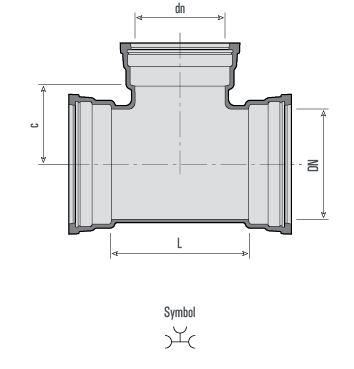

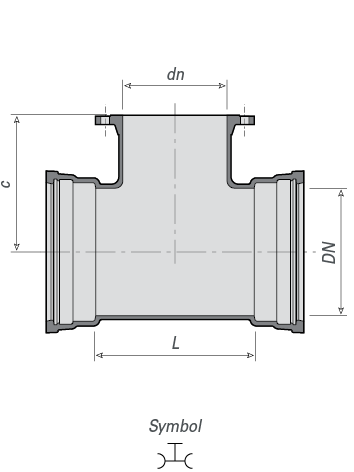

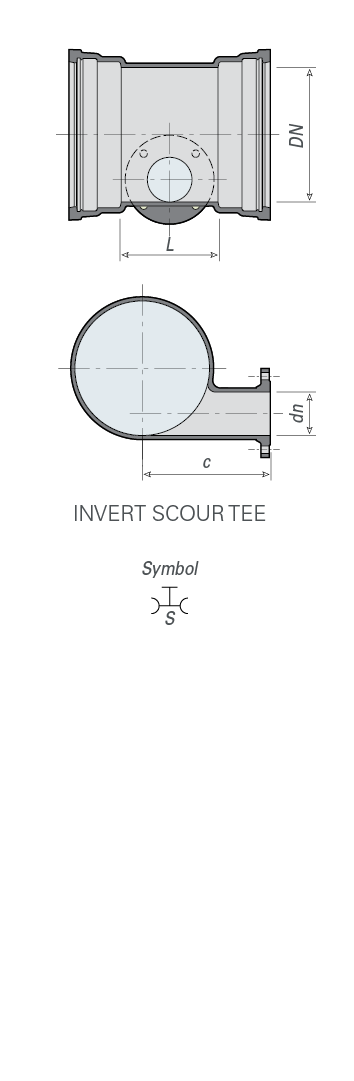

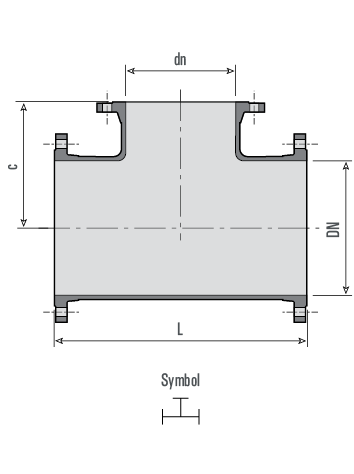

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 80 |

||

80 |

170 |

85 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 100 |

||

80 |

170 |

95 |

100 |

190 |

95 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 150 |

||

80 |

170 |

120 |

100 |

195 |

120 |

150 |

255 |

125 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 200 |

||

80 |

175 |

145 |

100 |

200 |

145 |

150 |

255 |

150 |

200 |

315 |

155 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 250 |

||

80 |

180 |

170 |

100 |

200 |

170 |

150 |

260 |

175 |

200 |

315 |

180 |

250 |

375 |

190 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 300 |

||

M80 |

180 |

195 |

100 |

205 |

195 |

150 |

260 |

200 |

200 |

320 |

205 |

250 |

375 |

210 |

300 |

435 |

220 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 350 |

||

M80 |

185 |

220 |

M100 |

210 |

225 |

M150 |

265 |

230 |

M200 |

320 |

235 |

M250 |

380 |

240 |

M300 |

440 |

245 |

M350 |

495 |

250 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 400 |

||

M80 |

190 |

245 |

M100 |

210 |

245 |

M150 |

270 |

250 |

M200 |

325 |

255 |

M250 |

385 |

260 |

M300 |

440 |

270 |

M350 |

500 |

275 |

M400 |

560 |

280 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 450 |

||

M80 |

190 |

270 |

M100 |

215 |

270 |

M150 |

270 |

275 |

M200 |

330 |

285 |

M250 |

390 |

290 |

M300 |

445 |

295 |

M350 |

505 |

300 |

M400 |

560 |

305 |

M450 |

620 |

310 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 500 |

||

M80 |

190 |

270 |

M100 |

215 |

295 |

M150 |

275 |

300 |

M200 |

330 |

310 |

M250 |

390 |

315 |

M300 |

450 |

320 |

M350 |

505 |

325 |

M400 |

565 |

330 |

M450 |

620 |

335 |

M500 |

680 |

340 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 600 |

||

M80 |

200 |

345 |

M100 |

220 |

345 |

M150 |

280 |

350 |

M200 |

340 |

360 |

M250 |

395 |

365 |

M300 |

455 |

370 |

M350 |

510 |

375 |

M400 |

570 |

380 |

M450 |

630 |

385 |

M500 |

685 |

390 |

M600 |

800 |

400 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 700 |

||

M80 |

225 |

400 |

M100 |

230 |

400 |

M150 |

285 |

400 |

M200 |

345 |

405 |

M250 |

400 |

415 |

M300 |

460 |

420 |

M350 |

520 |

425 |

M400 |

575 |

430 |

M450 |

635 |

435 |

M500 |

690 |

440 |

M600 |

810 |

450 |

M700 |

925 |

460 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 800 |

||

M80 |

250 |

450 |

M100 |

270 |

460 |

M150 |

330 |

460 |

M200 |

380 |

460 |

M250 |

410 |

465 |

M300 |

465 |

470 |

M350 |

525 |

475 |

M400 |

580 |

480 |

M450 |

640 |

485 |

M500 |

700 |

490 |

M600 |

815 |

500 |

M700 |

930 |

510 |

M800 |

1045 |

525 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 900 |

||

M80 |

225 |

625 |

M100 |

270 |

630 |

M150 |

355 |

630 |

200 |

355 |

645 |

M250 |

415 |

655 |

M300 |

470 |

660 |

M350 |

530 |

670 |

400 |

590 |

675 |

M450 |

645 |

685 |

M500 |

705 |

690 |

600 |

1170 |

705 |

M700 |

935 |

720 |

M800 |

1050 |

735 |

900 |

1170 |

750 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 1000 |

||

M80 |

260 |

685 |

M100 |

360 |

690 |

M150 |

360 |

700 |

200 |

360 |

705 |

M250 |

420 |

715 |

M300 |

480 |

720 |

M350 |

535 |

730 |

400 |

595 |

735 |

M450 |

650 |

745 |

M500 |

710 |

750 |

600 |

1290 |

765 |

M700 |

940 |

780 |

M800 |

1060 |

795 |

900 |

1175 |

810 |

1000 |

1290 |

825 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 80 |

||

80 |

170 |

165 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 100 |

||

80 |

170 |

175 |

100 |

190 |

180 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 150 |

||

80 |

170 |

205 |

100 |

195 |

210 |

150 |

255 |

220 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 200 |

||

80 |

175 |

235 |

100 |

200 |

240 |

150 |

255 |

250 |

200 |

315 |

260 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 250 |

||

80 |

180 |

265 |

100 |

200 |

270 |

150 |

260 |

280 |

200 |

315 |

290 |

250 |

375 |

300 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 300 |

||

80 |

180 |

295 |

100 |

205 |

300 |

150 |

260 |

310 |

200 |

320 |

320 |

B250 |

380 |

330 |

300 |

435 |

340 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 350 |

||

B80 |

185 |

325 |

100 |

205 |

330 |

B150 |

270 |

340 |

200 |

325 |

350 |

B250 |

385 |

360 |

M300 |

440 |

370 |

350 |

495 |

380 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 400 |

||

80 |

185 |

355 |

100 |

210 |

360 |

150 |

270 |

370 |

200 |

325 |

380 |

B250 |

385 |

390 |

300 |

440 |

400 |

M350 |

500 |

410 |

400 |

560 |

420 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 450 |

||

B100 |

215 |

390 |

B150 |

270 |

400 |

B200 |

330 |

410 |

B250 |

390 |

420 |

B300 |

445 |

430 |

B400 |

560 |

450 |

B450 |

620 |

460 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 500 |

||

M80 |

M205 |

415 |

100 |

215 |

420 |

M150 |

275 |

430 |

200 |

330 |

440 |

M250 |

390 |

450 |

M300 |

450 |

460 |

M350 |

505 |

470 |

400 |

565 |

480 |

M450 |

620 |

490 |

500 |

680 |

500 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 600 |

||

M80 |

200 |

475 |

M100 |

220 |

480 |

M150 |

280 |

490 |

200 |

340 |

500 |

M250 |

395 |

510 |

M300 |

455 |

520 |

M350 |

510 |

530 |

400 |

570 |

540 |

M450 |

630 |

550 |

M500 |

685 |

560 |

600 |

800 |

580 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 700 |

||

M80 |

225 |

505 |

M100 |

230 |

510 |

M150 |

285 |

520 |

200 |

345 |

525 |

M250 |

400 |

535 |

M300 |

460 |

540 |

M350 |

520 |

550 |

400 |

575 |

555 |

M450 |

635 |

565 |

M500 |

690 |

570 |

M600 |

810 |

585 |

700 |

925 |

600 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 800 |

||

M80 |

250 |

565 |

M100 |

270 |

570 |

M150 |

330 |

580 |

200 |

350 |

585 |

M250 |

410 |

595 |

M300 |

465 |

600 |

M350 |

525 |

610 |

400 |

580 |

615 |

M450 |

640 |

625 |

M500 |

700 |

630 |

600 |

1045 |

645 |

M700 |

930 |

660 |

800 |

1045 |

675 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 800 |

||

M80 |

225 |

625 |

M100 |

270 |

630 |

M150 |

355 |

630 |

200 |

355 |

645 |

M250 |

415 |

655 |

M300 |

470 |

660 |

M350 |

530 |

670 |

400 |

590 |

675 |

M450 |

645 |

685 |

M500 |

705 |

690 |

600 |

1170 |

705 |

M700 |

935 |

720 |

M800 |

1050 |

735 |

900 |

1170 |

750 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN1000 |

||

M80 |

260 |

685 |

M100 |

360 |

690 |

M150 |

360 |

700 |

200 |

360 |

705 |

M250 |

420 |

715 |

M300 |

480 |

720 |

M350 |

535 |

730 |

400 |

595 |

735 |

M450 |

650 |

745 |

M500 |

710 |

750 |

600 |

1290 |

765 |

M700 |

940 |

780 |

M800 |

1060 |

795 |

900 |

1175 |

810 |

1000 |

1290 |

825 |

Nominal Size |

Dimension |

|||

DN |

dn |

L |

c |

|

M200 |

80 |

175 |

235 |

|

M250 |

80 |

180 |

265 |

|

M300 |

80 |

180 |

295 |

|

M350 |

100 |

205 |

330 |

|

M400 |

100 |

210 |

360 |

|

M450 |

100 |

215 |

390 |

|

M500 |

100 |

215 |

420 |

|

M600 |

100 |

220 |

480 |

|

M700 |

150 |

345 |

520 |

|

M700 |

200 |

345 |

525 |

|

M800 |

150 |

350 |

580 |

|

M800 |

200 |

350 |

585 |

|

For sizes above DN 1000 please refer to your SuperTYT Australia |

||||

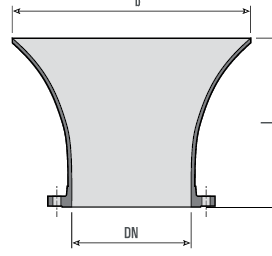

Nominal Size |

Dimension |

DN |

t |

M80 |

18 |

M100 |

18 |

M150 |

18 |

M200 |

18 |

M250 |

19.5 |

M300 |

23 |

M350 |

24 |

M400 |

25 |

M450 |

26 |

M500 |

27 |

M600 |

29.5 |

M700 |

31 |

M800 |

33 |

M900 |

35 |

M1000 |

37 |

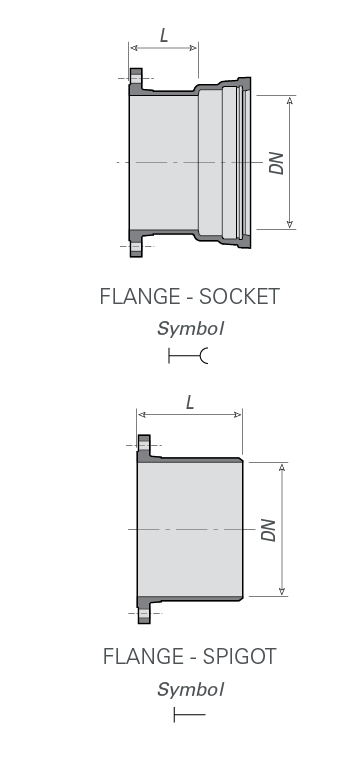

Nominal Size |

Dimension |

DN |

L |

Flange - Socket |

|

80 |

130 |

100 |

130 |

150 |

135 |

200 |

140 |

250 |

145 |

300 |

150 |

350 |

155 |

400 |

160 |

450 |

165 |

500 |

170 |

600 |

180 |

700 |

190 |

800 |

200 |

900 |

210 |

1000 |

220 |

Nominal Size |

Dimension |

DN |

L |

Flange - Spigot |

|

80 |

350 |

100 |

360 |

150 |

380 |

200 |

400 |

250 |

420 |

300 |

440 |

350 |

460 |

400 |

480 |

450 |

500 |

500 |

520 |

600 |

560 |

700 |

600 |

800 |

600 |

900 |

600 |

1000 |

600 |

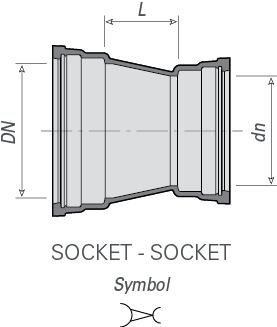

Nominal Size |

Dimension |

|

DN |

dn |

L |

100 |

80 |

90 |

150 |

80 |

190 |

150 |

100 |

150 |

200 |

100 |

250 |

200 |

150 |

150 |

250 |

150 |

250 |

250 |

200 |

150 |

300 |

150 |

350 |

300 |

200 |

250 |

300 |

250 |

150 |

350 |

200 |

360 |

350 |

250 |

260 |

350 |

300 |

160 |

M400 |

200 |

460 |

400 |

250 |

360 |

400 |

300 |

260 |

400 |

350 |

160 |

M450 |

250 |

460 |

M450 |

300 |

360 |

450 |

350 |

260 |

450 |

400 |

160 |

M500 |

250 |

560 |

Nominal Size |

Dimension |

|

DN |

dn |

L |

M500 |

300 |

460 |

500 |

350 |

360 |

500 |

400 |

260 |

M500 |

450 |

160 |

M600 |

300 |

660 |

M600 |

350 |

560 |

600 |

400 |

460 |

M600 |

450 |

360 |

600 |

500 |

260 |

M700 |

450 |

580 |

700 |

500 |

480 |

700 |

600 |

280 |

M800 |

500 |

680 |

800 |

600 |

480 |

800 |

700 |

280 |

900 |

M80 |

1720 |

900 |

M100 |

1680 |

900 |

M150 |

1580 |

900 |

M200 |

1480 |

900 |

M250 |

1380 |

900 |

M300 |

1280 |

Nominal Size |

Dimension |

|

DN |

dn |

L |

900 |

M350 |

1180 |

900 |

M400 |

1080 |

900 |

M450 |

980 |

900 |

M500 |

880 |

900 |

M600 |

680 |

900 |

700 |

480 |

900 |

800 |

280 |

1000 |

M80 |

1920 |

1000 |

M100 |

1880 |

1000 |

M150 |

1780 |

1000 |

M200 |

1680 |

1000 |

M250 |

1580 |

1000 |

M300 |

1480 |

1000 |

M350 |

1380 |

1000 |

M400 |

1280 |

1000 |

M450 |

1180 |

1000 |

M500 |

1080 |

1000 |

M600 |

880 |

1000 |

M700 |

680 |

1000 |

800 |

480 |

1000 |

900 |

280 |

Nominal Size |

Dimension |

|||

b |

||||

DN |

11¼˚ Bends |

22½˚ Bends |

45˚ Bends |

90˚ Bends |

80 |

113 |

105 |

130 |

165 |

100 |

115 |

110 |

140 |

180 |

150 |

113 |

109 |

160 |

220 |

200 |

132 |

131 |

180 |

260 |

250 |

165 |

190 |

350 |

350 |

300 |

175 |

210 |

400 |

400 |

350 |

191 |

210 |

298 |

450 |

400 |

205 |

239 |

324 |

500 |

450 |

349 |

349 |

350 |

550 |

500 |

375 |

375 |

375 |

600 |

600 |

426 |

426 |

426 |

700 |

700 |

478 |

478 |

478 |

800 |

800 |

529 |

529 |

529 |

900 |

900 |

581 |

581 |

581 |

1000 |

1000 |

632 |

632 |

632 |

1100 |

|

For sizes above DN 1000 refer to your SuperTYT representative. |

||||

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 80 |

||

80 |

330 |

165 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 100 |

||

80 |

360 |

175 |

100 |

360 |

180 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 150 |

||

80 |

440 |

205 |

100 |

440 |

210 |

150 |

440 |

220 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 200 |

||

80 |

520 |

235 |

100 |

520 |

240 |

150 |

520 |

250 |

200 |

520 |

260 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 250 |

||

B80 |

405 |

265 |

100 |

700 |

275 |

B150 |

485 |

280 |

200 |

700 |

325 |

250 |

700 |

350 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 300 |

||

B80 |

425 |

295 |

100 |

800 |

300 |

B150 |

505 |

310 |

200 |

800 |

350 |

B250 |

620 |

330 |

300 |

800 |

400 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 350 |

||

B80 |

445 |

325 |

100 |

850 |

325 |

B150 |

530 |

340 |

200 |

850 |

325 |

B250 |

645 |

360 |

M300 |

850 |

425 |

350 |

850 |

425 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 400 |

||

B80 |

470 |

355 |

100 |

900 |

350 |

B150 |

550 |

370 |

200 |

900 |

350 |

B250 |

665 |

390 |

B300 |

725 |

400 |

M350 |

900 |

450 |

400 |

900 |

450 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 450 |

||

100 |

950 |

375 |

B150 |

570 |

400 |

200 |

950 |

375 |

B250 |

690 |

420 |

B300 |

745 |

430 |

M350 |

950 |

475 |

B400 |

860 |

450 |

450 |

950 |

475 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 500 |

||

100 |

1000 |

400 |

M150 |

1000 |

400 |

200 |

1000 |

400 |

M250 |

1000 |

400 |

M300 |

1000 |

500 |

M350 |

1000 |

500 |

400 |

1000 |

500 |

M450 |

1000 |

500 |

500 |

1000 |

500 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 600 |

||

200 |

1100 |

450 |

M250 |

1100 |

450 |

M300 |

1100 |

550 |

M350 |

1100 |

550 |

400 |

1100 |

550 |

M450 |

1100 |

550 |

M500 |

1100 |

550 |

600 |

1100 |

550 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 700 |

||

200 |

650 |

525 |

M250 |

705 |

533 |

M300 |

760 |

540 |

M350 |

815 |

548 |

400 |

870 |

555 |

M450 |

925 |

563 |

M500 |

980 |

570 |

M600 |

1200 |

585 |

700 |

1200 |

600 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 800 |

||

200 |

690 |

585 |

M250 |

745 |

593 |

M300 |

800 |

600 |

M350 |

855 |

608 |

400 |

910 |

615 |

M450 |

965 |

623 |

M500 |

1020 |

630 |

600 |

1350 |

645 |

M700 |

1350 |

660 |

800 |

1350 |

675 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 900 |

||

M80 |

598 |

627 |

M100 |

620 |

630 |

M150 |

675 |

640 |

200 |

730 |

645 |

M250 |

785 |

655 |

M300 |

840 |

660 |

400 |

950 |

675 |

M450 |

1005 |

685 |

M500 |

1060 |

690 |

600 |

1500 |

705 |

M700 |

1500 |

735 |

M800 |

1500 |

735 |

900 |

1500 |

750 |

Nominal Size |

Dimension |

|

dn |

L |

c |

DN 1000 |

||

M80 |

638 |

685 |

M100 |

660 |

690 |

M150 |

715 |

700 |

200 |

770 |

705 |

M250 |

825 |

715 |

M300 |

880 |

720 |

M350 |

935 |

730 |

400 |

990 |

735 |

M450 |

1045 |

745 |

M500 |

1100 |

750 |

600 |

1650 |

765 |

M700 |

1650 |

765 |

M800 |

1650 |

795 |

M900 |

1650 |

825 |

1000 |

1650 |

825 |

For sizes above DN 1000 refer to your SuperTYT representative.

Nominal Size |

Dimension |

||

DN |

b |

I |

w |

80 |

165 |

110 |

180 |

100 |

180 |

125 |

200 |

150 |

220 |

160 |

250 |

200 |

260 |

190 |

300 |

250 |

350 |

225 |

350 |

300 |

400 |

255 |

400 |

350 |

450 |

290 |

450 |

400 |

500 |

320 |

500 |

450 |

550 |

355 |

550 |

500 |

600 |

385 |

600 |

600 |

700 |

450 |

700 |

M700 |

800 |

515 |

800 |

M800 |

900 |

580 |

900 |

M900 |

1000 |

645 |

1000 |

M1000 |

1100 |

710 |

1100 |

Nominal Size |

Dimension |

|

DN |

I |

b |

M80 |

130 |

150 |

M100 |

135 |

175 |

M150 |

150 |

230 |

M200 |

170 |

290 |

M250 |

185 |

345 |

M300 |

205 |

405 |

M350 |

220 |

460 |

M400 |

240 |

520 |

M450 |

255 |

575 |

M500 |

275 |

635 |

M600 |

310 |

750 |

M700 |

345 |

865 |

M800 |

380 |

980 |

M900 |

415 |

1095 |

M1000 |

450 |

1210 |

For sizes above DN 1000 refer to your SuperTYT representative.

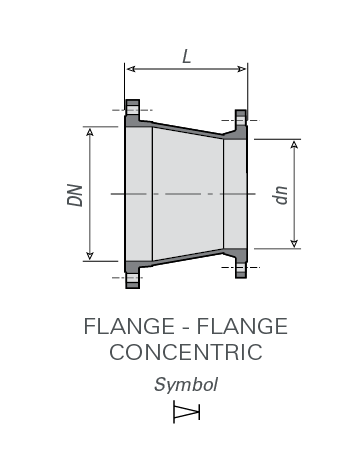

Nominal Size |

Dimension |

|

DN |

dn |

L |

CONCENTRIC |

||

M80 |

50 |

200 |

80 |

65 |

200 |

M100 |

50 |

300 |

M100 |

65 |

300 |

100 |

80 |

200 |

M150 |

80 |

400 |

M150 |

100 |

300 |

M200 |

80 |

150 |

M200 |

100 |

600 |

200 |

150 |

300 |

M250 |

150 |

600 |

250 |

200 |

300 |

M300 |

150 |

600 |

M300 |

200 |

600 |

300 |

250 |

300 |

M350 |

250 |

600 |

350 |

300 |

300 |

Nominal Size |

Dimension |

|

DN |

dn |

L |

CONCENTRIC |

||

M400 |

200 |

700 |

M400 |

250 |

650 |

400 |

300 |

300 |

400 |

350 |

300 |

M450 |

250 |

700 |

M450 |

300 |

650 |

M450 |

350 |

600 |

450 |

400 |

300 |

M500 |

250 |

750 |

M500 |

300 |

700 |

M500 |

350 |

650 |

500 |

400 |

600 |

M500 |

450 |

300 |

M600 |

300 |

800 |

M600 |

350 |

750 |

M600 |

400 |

700 |

M600 |

450 |

650 |

Nominal Size |

Dimension |

|

DN |

dn |

L |

CONCENTRIC |

||

600 |

500 |

600 |

M700 |

450 |

750 |

M700 |

500 |

700 |

700 |

600 |

600 |

M800 |

500 |

800 |

M800 |

600 |

700 |

800 |

700 |

600 |

M900 |

450 |

950 |

M900 |

500 |

900 |

M900 |

600 |

800 |

M900 |

700 |

700 |

900 |

800 |

600 |

M1000 |

500 |

1000 |

M1000 |

600 |

900 |

M1000 |

700 |

800 |

M1000 |

800 |

700 |

1000 |

900 |

600 |

For sizes above DN 800 refer to your SuperTYT representative.

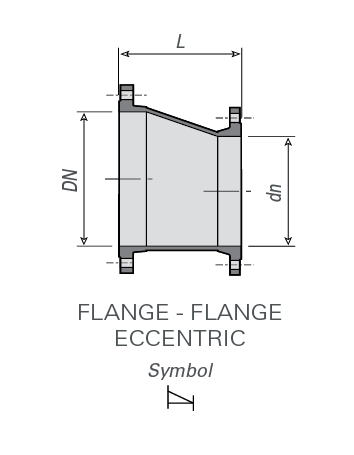

Nominal Size |

Dimension |

|

DN |

dn |

L |

Eccentric |

||

M80 |

50 |

200 |

80 |

65 |

200 |

M100 |

50 |

300 |

M100 |

65 |

300 |

100 |

80 |

200 |

M150 |

80 |

400 |

M150 |

100 |

300 |

M200 |

80 |

150 |

M200 |

100 |

600 |

200 |

150 |

300 |

M250 |

150 |

600 |

250 |

200 |

300 |

M300 |

150 |

600 |

M300 |

200 |

600 |

300 |

250 |

300 |

M350 |

250 |

600 |

350 |

300 |

300 |

Nominal Size |

Dimension |

|

DN |

dn |

L |

Eccentric |

||

M400 |

200 |

700 |

M400 |

250 |

650 |

400 |

300 |

300 |

400 |

350 |

300 |

M450 |

250 |

700 |

M450 |

300 |

650 |

M450 |

350 |

600 |

450 |

400 |

300 |

M500 |

250 |

750 |

M500 |

300 |

700 |

M500 |

350 |

650 |

500 |

400 |

600 |

M500 |

450 |

300 |

M600 |

300 |

800 |

M600 |

350 |

750 |

M600 |

400 |

700 |

M600 |

450 |

650 |

Nominal Size |

Dimension |

|

DN |

dn |

L |

Eccentric |

||

600 |

500 |

600 |

M700 |

450 |

750 |

M700 |

500 |

700 |

700 |

600 |

600 |

M800 |

500 |

800 |

M800 |

600 |

700 |

800 |

700 |

600 |

M900 |

450 |

950 |

M900 |

500 |

900 |

M900 |

600 |

800 |

M900 |

700 |

700 |

900 |

800 |

600 |

M1000 |

500 |

1000 |

M1000 |

600 |

900 |

M1000 |

700 |

800 |

M1000 |

800 |

700 |

1000 |

900 |

600 |

For sizes above DN 1000 refer to your SuperTYT representative.

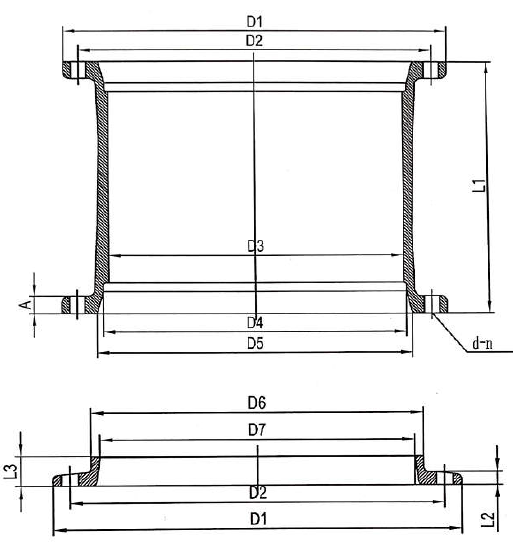

NOMINAL |

L1 |

D1 |

D2 |

D3 |

D4 |

D5 |

A |

d |

n |

D6 |

D7 |

L3 |

L2 |

80 |

325 |

205 |

165 |

104 |

112 |

130 |

18 |

19 |

4 |

126 |

102 |

35 |

16 |

100 |

325 |

234 |

188 |

121 |

130 |

148 |

19 |

23 |

4 |

146 |

122 |

35 |

16 |

150 |

330 |

288 |

242 |

173 |

182 |

200 |

20 |

23 |

6 |

198 |

174 |

36 |

17 |

200 |

340 |

341 |

295 |

225 |

234 |

252 |

20 |

23 |

6 |

250 |

226 |

37 |

18 |

250 |

385 |

395 |

349 |

277 |

286 |

304 |

21 |

23 |

8 |

302 |

278 |

38 |

19 |

300 |

400 |

455 |

409 |

329 |

342 |

360 |

22 |

23 |

8 |

354 |

330 |

39 |

20 |

350 |

405 |

508 |

462 |

382 |

394 |

412 |

23 |

23 |

10 |

406 |

382 |

40 |

21 |

400 |

410 |

561 |

515 |

433 |

445 |

463 |

23 |

23 |

12 |

457 |

433 |

41 |

22 |

450 |

435 |

614 |

568 |

484 |

496 |

514 |

24 |

23 |

12 |

509 |

485 |

42 |

23 |

500 |

440 |

667 |

621 |

536 |

548 |

566 |

25 |

23 |

14 |

560 |

536 |

43 |

24 |

600 |

450 |

773 |

727 |

639 |

651 |

669 |

26 |

23 |

14 |

663 |

639 |

44 |

25 |

700 |

520 |

892 |

838 |

743 |

758 |

780 |

28 |

27 |

16 |

773 |

743 |

45 |

26 |

800 |

550 |

999 |

942 |

847 |

862 |

884 |

29 |

27 |

20 |

877 |

847 |

47 |

28 |

900 |

590 |

1123 |

1057 |

950 |

965 |

987 |

31 |

33 |

20 |

980 |

950 |

48 |

29 |

1000 |

620 |

1231 |

1160 |

1054 |

1068 |

1090 |

32 |

33 |

20 |

1083 |

1054 |

49 |

30 |

For sizes above DN 1000 refer to your SuperTYT representative.